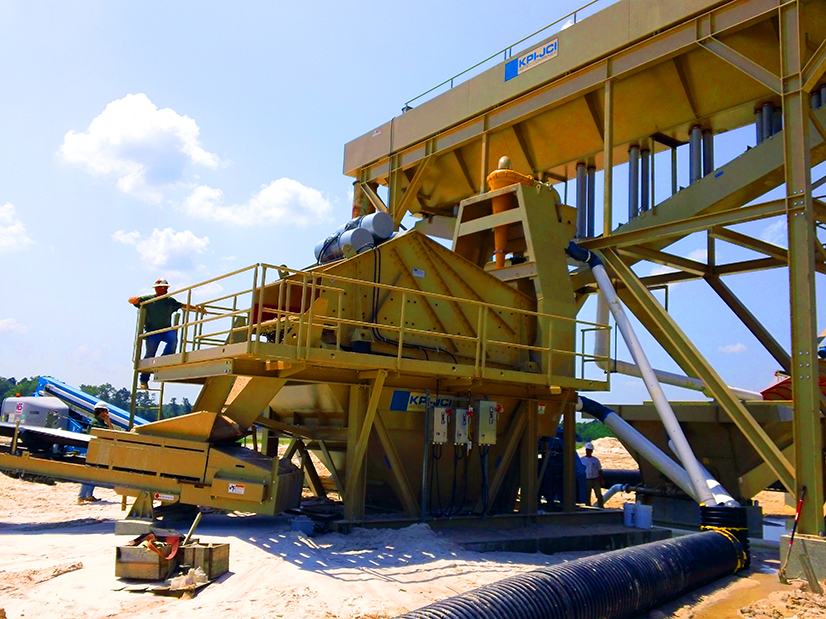

SAND PLANT HICKORY, LA

SAND PLANT HICKORY, LA

A customer came to us wanting a sand plant that could help them produce frac sand using a dredge to mine the sand. The other requirement was that they also wanted the ability to make traditional mason sand and concrete sand if the market on frac sand ever bottomed out. So with the help of Kolberg – Pioneer’s Carson Schott we came up with a design that wasn’t too far off of the convention way of making concrete sand. The first piece which is a 8x20 deck shaker, is used to separate gravel products from the sand. The gravel comes off the front which is then processed with an existing washing system. The sand with some small gravel is sent to an 11 station classifier where with the software package and water flow you can dial in the “a” and “b” products with a “c” product as a waste or a finer product. Now a classifier will not get you an exact spec normally used in the frac sand industry but it will allow you to put in parameters that will get you close.

Our customer started out making a concrete sand and a fine cut of frac sand a then running it across a dewatering a screen that multi-purpose. A they wanted the driest product possible before it hit the ground and they wanted to cut some off the bottom end of the sand and that was done with a cyclone. The concrete sand was made in the traditional way of blending the stations back in to a sand screw and stockpiling with radial stackers.

Here is a list of the Kolberg – Pioneer equipment used in the process.

- 8X20 low profile 2 deck Shaker Screen

- 12x48 classifying tank

- Twin 44” sand screw

- 36” x 150’ flat conveyor

- 36”x 100’ radial stacker

- 9200 plant / dewatering shaker and sump

- 36” x 150’ flat conveyor

- 36” x 100’ radial stacker